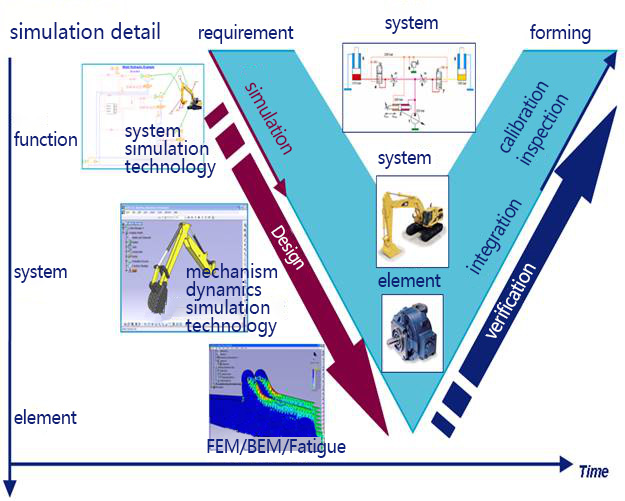

CAE research office is mainly engaged in the research of virtual prototype numerical simulation of key technologies and core problems of products, including dynamic analysis, system simulation, electromechanical and hydraulic integration analysis, etc. By using finite element method combined with fatigue life analysis, optimization design and other related theories and simulation programs, the technical problems in the development of various products are solved. Participated in the company in all areas important for the development of new products, especially in the fatigue life analysis and wind power generator plant of large tonnage crane seismic analysis and optimization design breakthroughs, successively Palngre-Miner linear cumulative damage theory, considering the factors such as the machining accuracy, fatigue life analysis was carried out on the fan, fan models applied in different design check and classification society certification. At the same time in our country, the design of a new generation of nuclear power technology project development, combined with the theory of spectrum analysis, transient dynamics theory and so on, completed the lack of considering quality modal residual stiffness response crane seismic analysis of the third generation of nuclear power plants, consider the circular crane manufacturing deviation time history analysis and optimization design of related research, popularization and application in national science and technology major projects corpus and all kinds of research and development of nuclear power crane, in the domestic and international advanced level. It has obtained more than 10 national authorized patents, formulated and completed one nuclear power product standard and more than 10 three-dimensional design standards.

CAE research office has mastered AUTOCAD,UG-NX, SolidWorks and other CAD software, as well as ANSYS,NX-Nastran, Simpack, ADAMS, Simufact, SimulationX, EDEM and other general finite element analysis software and dynamic analysis software. At the same time, relying on cloud computing platform and graphic workstation, simulation analysis can be carried out according to different requirements. Integrates the following fields: finite element the strength,(stiffness and stability of structure dynamic response, temperature, shock, etc.)the multi-body dynamics and fatigue durability, tax and acoustic analysis, fluid drive and electric drive system level modeling, control system, mechanical and electrical integration of liquid analysis, reliability analysis, visual simulation, etc.

CAD technician are mainly engaged in the construction, maintenance, upgrading, secondary development, specification formulation, training and technical promotion of CAD design platform of the technical center. CAE technical personnel are all postgraduate students from 985 colleges and universities. They are proficient in basic theories of various disciplines and corresponding simulation analysis software. They have rich engineering practical experience and CAEMC—CAE engineering management consultant certification with international registration. Team relying on mining equipment and state key laboratory of intelligent manufacturing, high-end heavy equipment manufacturing smart key science and technology innovation platform of Shanxi Province, Shanxi Province academician workstation and other heavy equipment intelligent manufacturing platform, with Zhejiang University, Jilin University, Northeast University, Dalian University of technology, such as production, cooperation, conduct the thorough research to the digital simulation technology for heavy machinery products.

CAE laboratory in nearly a decade chaired or participated in completed a total of more than one hundred various scientific research projects, which completed the national 863 project “75 cubic meters of large open-air mine excavator developed” neutron topic 2,national science and technology major projects “CAP1400 nuclear major equipment design technology research” corpus 1 item,3 provincial projects, the company more than 30 key development projects and technical center. The main projects completed in recent years are as follows:

ID

|

Project performance

|

1

|

Digital prototype of a complete set of double-column rapid forging hydraulic press equipment

|

2

|

Research on digital prototype of casting crane

|

3

|

Finite element analysis and optimization of key components of TZM500 full-road

|

4

|

Research on coupling seismic analysis of AP1000 nuclear crane and steel containment vessel

|

5

|

Optimization of bridge crane girder based on geometric parameters

|

6

|

Study on fatigue analysis and main influencing factors of wheel hub and spindle of wind turbine

|

7

|

Research on standardization of CAE analysis for leading products

|

8

|

Seismic analysis of crane in nuclear power plant based on time history response

|

9

|

Study on airflow distribution and heat dissipation characteristics in the engine room of wind turbine

|

10

|

Research on electromechanical cooperative simulation of excavator working device

|

11

|

Research on weld stress and fatigue life analysis method based on IIW international welding standard

|

12

|

Study on inertia force balance torsional vibration and dynamic response of main drive system of cold pilger mill

|

晋ICP备05004298 晋公网安备 14010902000286号