Technical services in terms of test and development include: static and dynamic stress test and deformation test for machine structure; fatigue test and life-span estimation of structure; vibration test and fault diagnosis; load calculation of wind turbine; assessment and qualification test for complete machine; scanned surveying, mapping and modeling for machine parts with complicate shape.

Main achievements for the past few years include: Trial test of 500/300/40t two-way gantry crane in Longyangxia on the Yellow River; Development of MDAS multi-channel data processing system; Qualification test of 320/20/2t gantry crane in Sanmenxia; Test and study of 12-housing micro-tension reducing mill in Anshan Iron & Steel Corporation; Strength test of 921 launch tower in Jiuquan Satellite Launch Center; Development of crane weighing and overload limiter; Strength test of 2.1m3 cold lift machine in 405 factory of Ministry of Nuclear Industry; Development of real-time strength and stiffness measuring system for 1200t overhead crane in Three Gorges Project; Fatigue life estimating of 400t ladle crane in Baoshan Iron & Steel Co. Ltd.; Loading test of 1200t overhead crane in Three Gorges Project; Turnbuckle stress test of Runyang Yangtze River Bridge; Strength test and assessment of 3# launch tower in Xichang Satellite Launch Center; Reliability test & fatigue life estimating of 120t, 450t ladle crane in Baoshan Iron & Steel Co. Ltd.; Strength test & erection monitoring for large structures of AP1000.

For the past few years, the Technical center is keeping pace with the development of modern measurement technique and bringing in new measurement methods successively. Hence, it can meet the changing technique requirements.

Stress and strain test method. The stress and strain can reflect the force and deformation level of machine under loading status. The measurement instruments include: dynamic stress instrument, static stress instrument, wireless strain measurement node.

Vibration test method. The vibration value of machine is one of the evidence that used to judge whether the machine runs well or not. The measurement instruments include: smart cloud acquisition instrument from COINV, charge amplifier, wireless vibration node.

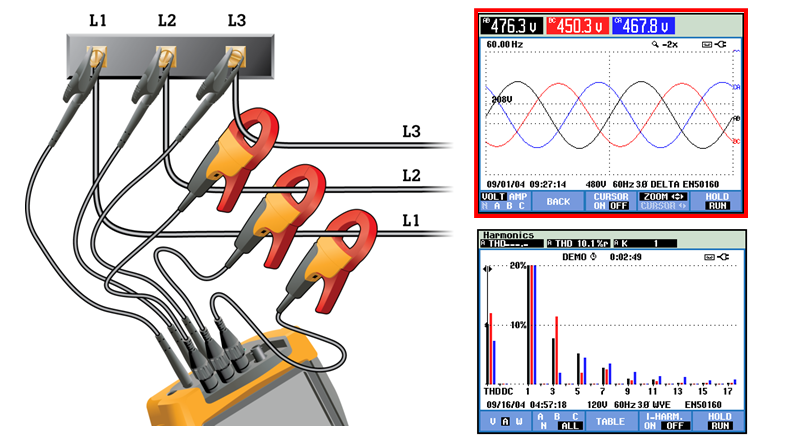

Parameters of electric system test method. There are various kinds of parameters that reflect the running status of electric system, such as value of voltage, electric current, and power; power factor; harmonic wave; three-phase imbalance. The measurement instruments include: Fluke190-202 scopemeter, Fluke 1760 power quality analyzer.

。Parameters of hydraulic system test method. Pressure test and oil quality test are included.

![]()

Geometric sense measurement method. There is a Topcon GPT3000 total station that is used to measure the three-dimensional coordinate of a given point in space or the geometrical relationship between points. It is usually used to measure deformation of a structure under loading. A advanced optical measurement technique is used in the three-dimensional photogrammetry measurement system, which is quite applicable to survey and map machine parts with complicate shape after which one contour plot is generated in computer.

3-D Photogrammetry System

Other test methods. Laser range finder, digital multimeter, anemograph, pressure gage, tempil gun, thickness gauge and other instruments are included.

A professional measurement and control laboratory is founded in the Technical Center. Several laboratories including vibration analysis and fault diagnosis lab, strength analysis and stress inspection lab, transducer design and life-span evaluation lab, electrical logging lab and fatigue lab are set. Technical services in terms of test and development are provided including: static and dynamic stress test for machine structure; fatigue test and life-span estimation of structure; vibration test and fault diagnosis; load calculation of wind turbine; assessment and qualification test for complete machine; scanned surveying, mapping and modeling for machine parts with complicate shape.

晋ICP备05004298 晋公网安备 14010902000286号