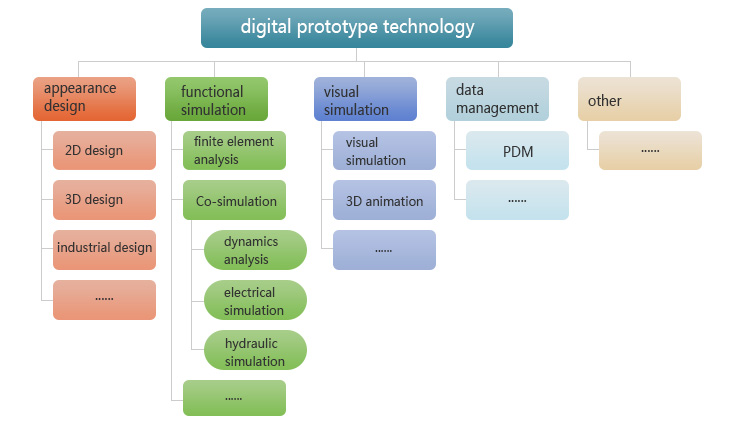

Digital prototype platform integrates the following disciplines: finite element (strength, stiffness, stability, dynamic response, temperature field, impact, etc); multi-body dynamics; fatigue durability; vibration and acoustic analysis; fluid transmission; electric drive and other system-level modeling analysis; control system analysis; electrohydraulic integration analysis; reliability analysis; visual simulation.

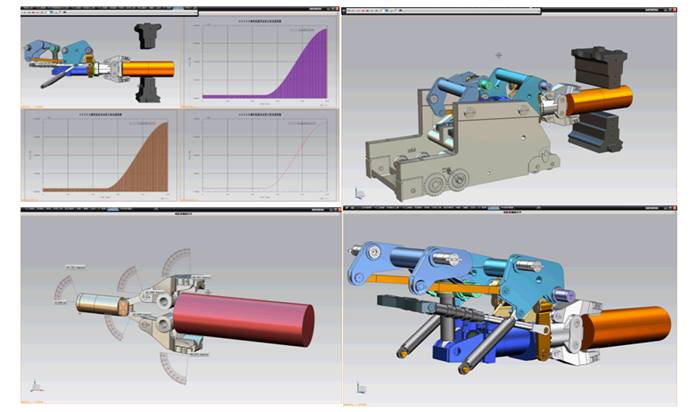

400KN manipulator multi-body dynamics analysis

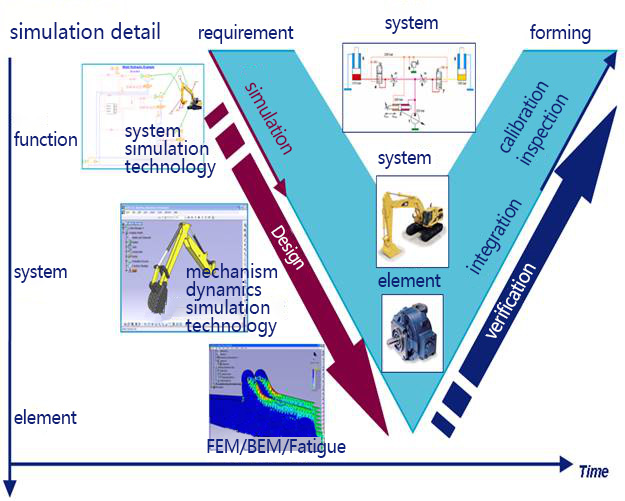

In the stage of overall scheme design, system-level modeling technology is used to model fluid transmission, electrical system and control system. Through steady stage, dynamic and frequency domain analysis, the overall scheme and architecture of the system are determined and optimized. Through the simulation analysis in this stage, on the one hand, the overall design scheme of the system can be optimized, on the other hand, the design objective can be decomposed into subsystems and parts, and the specifications of subsystems and parts can be further determined. Ensure that the subsystem and parts are compatible and matched.

integration of digital prototype platform and design process

As an important part and front-end technology of intelligent manufacturing, digital design technology presents a broad application prospect. The technology center combines the development of advanced design technology, aiming at the characteristics of heavy equipment, such as complex working conditions, sudden change of load, high reliability requirements and multi-disciplinary technology integration, the digital prototype technology is adopted to realize the functional verification, performance prediction and process simulation of the design stage, and the independent R&D capability of the center is improved.

Through modeling and combination simulation of mechanical, electrical and hydraulic systems for heavy equipment, the results of kinematics, dynamics and finite element analysis are obtained, and the visual integration of multi-disciplinary and multi-performance engineering analysis data is realized. The geometry, function and performance models of heavy equipment are described, analyzed and managed by digital technology. The operating tools are computer and its supporting software, including conceptual design(industrial design) software, CAD(two-dimensional, three-dimensional, mechanical, electrical etc), CAE, visual simulation software. At present, the technology center has carried out a lot of research work in the aspects of dynamic load prediction based on big data, mechanical parameterized design method, and multi-disciplinary integrated design of machine-electric-hydro-control.

晋ICP备05004298 晋公网安备 14010902000286号