The intellectualized crane developed by technical center deeply integrates advanced sensor technology, wireless communication, drive control system,PLC processing technology , internet of things and the internet + technology. Manual control is replaced while the safety and reliability is improved, resulting in the decreasing of personnel and increasing of efficiency. Also, the aims of high efficient and environmental protection are achieved. Moreover, by seamlessly integrated with the plant management system, the system stability and production efficiency are enhanced.

According to the features of TZ products, researches combined with intelligent production line will be conducted on intelligent operation, intelligent diagnosis, active maintenance and health management. We will supply safe and reliable equipment to our customers and offer advanced solution for the construction of smart factory.

As a domestic professional designer and manufacturer for rolling equipment, TZ continuously applies intelligent and information technology to rolling equipment, and realizes accurate and fast seamless docking of many links such as production, testing, control and management, which not only provides systematic data sources for iron and steel enterprises, but also improves the business process and enterprise management level to a certain extent.

At present, the intellectualization of TZ rolling equipment is characterized by state perception, real-time analysis, autonomous decision-making, precise execution and improvement of learning. Automation control system, data acquisition system, data analysis system, process calculation and simulation system have been successfully studied. Digital twin virtual factory, production process visualization, process model and machine self-learning, intelligent production organization, analysis and decision-making, environmental protection monitoring and other functions have been realized.

In the future, TZ will base on big data, Internet of Things, cloud computing and modern communication technology, with information monitoring, model control and system optimization as its main contents.the aim is to promote the development of new generation rolling automation technology towards green, information and intelligence, and realize the unmanned operation mode for metallurgical process industry as soon as possible.

The research and development of heavy forging products has been developing towards large-scale, high-end and intelligent direction. Through the research of product intelligent design, advanced mechanical design, electrical design, numerical analysis, process and visual simulation software are actively applied. Advanced methods such as standardized and modular special design tools and embedded intelligent process software packages are developed. Advanced technologies such as data acquisition system, distributed control system, online fault diagnosis and remote operation and maintenance service are applied. With the goal of digitalization prototype and digitalization workshop, the intelligent level of forging products is constantly improved.

In the future, the research on Intelligent forging products will focus on improving product design data management system and establishing intelligent health management and service support platform for products, involving early warning of working environment, fault diagnosis and self-repair, maintenance scheme and execution of virtual equipment, analysis platform of product environmental protection indicators and life cycle management platform of product core accessories, etc.

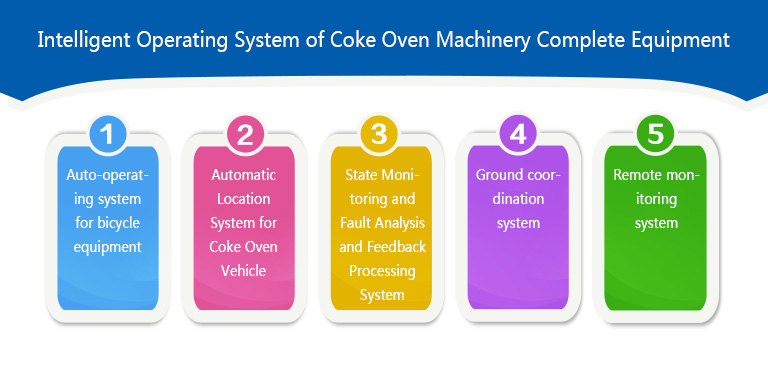

The traditional coking equipment has realized the intellectualization of the equipment by adopting advanced positioning technology, sensing technology, wireless communication technology, transmission control technology and PLC processing technology, replacing manual operation, improving the safety, reliability and environmental protection of the coke oven equipment, and being able to manage the plant at the same time. The system seamlessly docks and realizes real-time data exchange.

At present, the coking equipment developed independently by Too Heavy has realized the automation of each vehicle unit, chain control of each vehicle, data acquisition and fault diagnosis, initially built the health management system platform, and realized the anti-collision protection between vehicles.

Combining with the characteristics of the complete coking equipment, the future research will focus on Intelligent operation, intelligent diagnosis, active maintenance and health management, so as to realize the complete coking equipment "unmanned operation, manned duty" and provide users with safe, reliable, efficient and environmentally friendly equipment.

晋ICP备05004298 晋公网安备 14010902000286号